“The Global Austenitic Manganese Steel Market report provides information by Top Players, Geography, End users, Applications, Competitor analysis, Sales, Revenue, Price, Gross Margin, Market Share, Import-Export, Trends and Forecast.

Initially, the report provides a basic overview of the industry including definitions, classifications, applications and industry chain structure. The Austenitic Manganese Steel market analysis is provided for the international markets including development trends, competitive landscape analysis, and key regions development status.

Complete Report on Austenitic Manganese Steel market spread across 107 pages and Top companies. Get SAMPLE at https://inforgrowth.com/sample-request/3252439/austenitic-manganese-steel-market

2018 Global Austenitic Manganese Steel Market Report is a professional and in-depth research report on the world’s major regional market conditions of the Austenitic Manganese Steel industry, focusing on the main regions and the main countries (United States, Europe, Japan and China).

Global Austenitic Manganese Steel market competition by top manufacturers, with production, price, revenue (value) and market share for each manufacturer.

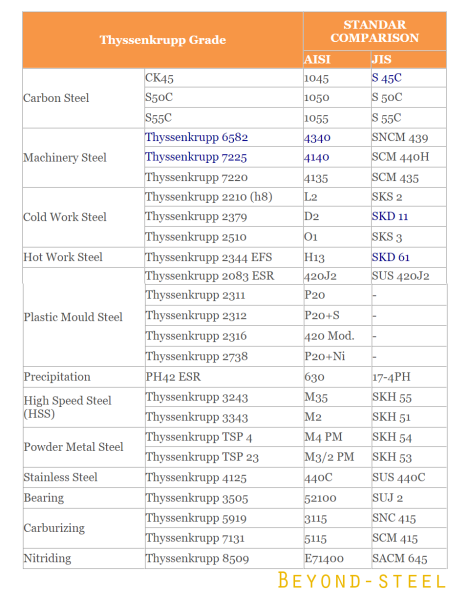

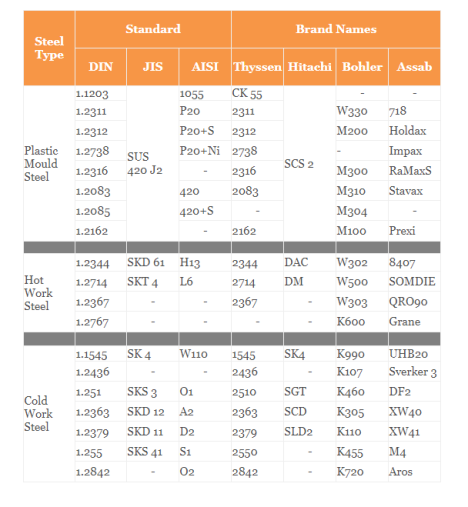

The Top players are Acme Alloys, Nippon Steel&Sumitomo Metal, Baosteel, ThyssenKrupp Steel Europe, JFE Steel, ECSO, Tata Steel Group, Titus Steel.

On the basis of product, report split into Panel, Bar, Others.

On the basis of the end users/applications, this report focuses on the status and outlook for major applications/end users, consumption (sales), market share and growth rate for each application, including Automotive, Construction, Others.

The report introduces Austenitic Manganese Steel basic information including definition, classification, application, industry chain structure, industry overview, policy analysis, and news analysis. Insightful predictions for the Austenitic Manganese Steel market for the coming few years have also been included in the report.

Development policies and plans are discussed as well as manufacturing processes and cost structures are also analyzed. This report also states import/export consumption, supply and demand Figures, cost, price, revenue and gross margins.

The report focuses on global major leading Austenitic Manganese Steel Market players providing information such as company profiles, product picture and specification, capacity, production, price, cost, revenue and contact information. Upstream raw materials and equipment and downstream demand analysis is also carried out.

The Austenitic Manganese Steel industry development trends and marketing channels are analyzed. Finally the feasibility of new investment projects are assessed and overall research conclusions offered.

Table of Contents

1 Austenitic Manganese Steel Market Overview

2 Global Austenitic Manganese Steel Market Competition by Manufacturers

3 Global Austenitic Manganese Steel Capacity, Production, Revenue (Value) by Region (2013-2018)

4 Global Austenitic Manganese Steel Supply (Production), Consumption, Export, Import by Region (2013-2018)

5 Global Austenitic Manganese Steel Production, Revenue (Value), Price Trend by Type

6 Global Austenitic Manganese Steel Market Analysis by Application

7 Global Austenitic Manganese Steel Manufacturers Profiles/Analysis

8 Austenitic Manganese Steel Manufacturing Cost Analysis

9 Industrial Chain, Sourcing Strategy and Downstream Buyers

10 Marketing Strategy Analysis, Distributors/Traders

11 Market Effect Factors Analysis

12 Global Austenitic Manganese Steel Market Forecast (2018-2024)

13 Research Findings and Conclusion

14 Appendix

For any custom research on this topic or any related topics, share your specific interest for custom-reports by clicking here https://inforgrowth.com/enquiry/3252439/austenitic-manganese-steel-market

Filed under: Carbon steel | Tagged: austenitic manganese steel application, high manganese steel plate, importir high manganese steel plate, manganese steel plate, plat mangan, plate mangan impor | Leave a comment »