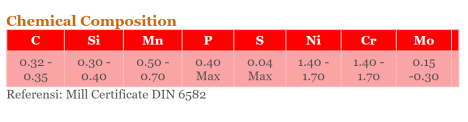

6582 is a low alloy steel which comprises of 1.8% nickel, chromium and molybdenum, high hardenability and is capable of giving good properties in large sections. It is relatively free from temper brittleness and retains useful machinability at relatively high hardness. Generally, Grade 6582 supplied in the condition of qunched and tempered in the tensile range of 930 – 1080 Mpa (condition U) – (Rc 28 – 36). Characterised by high strength and toughness in relatively large sections. Pre hardened and tempered 6582 can be further surface hardened by flame or induction hardeningand by nitriding.

All help enhance high strength and qunching ability Result from quenching is 54-59 HRC and can applied in high temperature task due to its properties of temper embrittlement. It suits and convenient for further hardening uch as induction. Besides it can also do nitriding or nitro carburizeing which will be better for resistance to wear and abrasive. Caution in application of 6582 I when tempering up to 1400 Mpa , steel might be brittle due to hydrogen embrittlement. So, it require hydrogen degassing for further pickling or plating. Tempering at hardness in the range of 1500-1950 Mpa, will be at risk of crack due to tension and stress corrosion cracking. Steel 6582 is used in most industry sectors for applications requiring higher tensile/yield strength than steel AISI 4140 can provide.

Outstanding Properties

• High Strength

• High toughness

• High forgability

• High ductility, bending is possible

• Resistance to fatigue

• Resistance to abrasive

• Machining ability is at moderate

• Not good for welding.

• Easy to quench and can do re quenching.

• Quenching up to 54-59 HRC

• Resistance to temper embrittlement

• Good for induction

• Can do Nitriding , surface hardness can reach to 650 HV

Availability

Round bar

Sizes Available : 20mm – 300mm

Hardening Temp : 820 – 850 C

Ouenching Medium : Oil

Hardness as Supplied : 220 – 250 BHN

Mechanical Properties

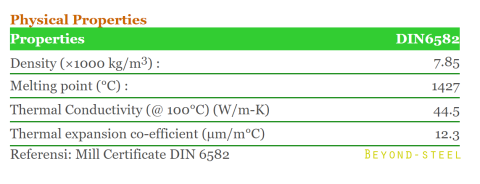

Physical Properties

Applications

Automotive crankshafts and rear axle shafts, aircrafts crankshafts, Connecting Rods, Propeller Hubs, Gears, Drive shafts, Landing gear parts and heavy duty parts of rock drill, Heavy Duty Shafts, Gears, Axles, Spindles, Couplings, Pins

Filed under: Round bar | Tagged: 35NCD6, 38Ch2N2MA, 6582 steel roundbar, ASSAB 705, Axle, baja, baja 6582, baja poros 6582, besi as, beyond-steel, Crankshaft, DIN 34NiCrMo6, EN24 817M40, Equivalent 6582, High Tensile Nickel Chrome Steel, indonesia, JIS SNCM 439, material baja pre hardened, material lentur 4340 annealed, round bar, Steel AISI 4340, Thysenkrupp 6582 jakarta, Truck Parts and Repair, VCN 150 | 2 Comments »